Corning® Valor® Glass is a revolutionary primary pharmaceutical glass package.

We’ve applied our expertise in glass science, optical physics, vapor deposition, precision forming, and extrusion to design and develop a 21st century glass container to protect 21st century drugs and vaccines. Corning Valor glass vials enhance the storage and delivery of drugs, providing more reliable access to medicines essential to public health.

Corning Valor Glass Attributes

Chemically Durable Drug Contacting Surface

Innovated from the inside out

Chemically Durable Drug Contacting Surface

Valor pharmaceutical packaging meets USP Type I hydrolytic criteria with a pristine, chemically durable drug contacting surface. The composition and uniform interior surface of Valor glass containers eliminate delamination and have low extractable concentrations – making them ideally-suited to protect drug products. Potentially harmful elements such as arsenic are not added to the Valor glass composition.

Valor pharmaceutical packaging meets USP Type I hydrolytic criteria with a pristine, chemically durable drug contacting surface. The composition and uniform interior surface of Valor glass containers eliminate delamination and have low extractable concentrations – making them ideally-suited to protect drug products. Potentially harmful elements such as arsenic are not added to the Valor glass composition.

Resists Damage and Breakage

Giving medicine the protection it deserves

Resists Damage and Breakage

Valor pharmaceutical glass packaging is the ultimate medical glass solution for all pharmaceutical filling environments. Valor glass is inherently strong and damage resistant, making it better able to withstand extreme events during pharmaceutical processing and field applications. These more robust pharmaceutical glass vials and containers also reduce down time due to glass-related interventions and provide enhanced protection for medicines in the hands of end users.

Valor pharmaceutical glass packaging is the ultimate medical glass solution for all pharmaceutical filling environments. Valor glass is inherently strong and damage resistant, making it better able to withstand extreme events during pharmaceutical processing and field applications. These more robust pharmaceutical glass vials and containers also reduce down time due to glass-related interventions and provide enhanced protection for medicines in the hands of end users.

Reduces Glass Particulate Generation

The package for purity

Reduces Glass Particulate Generation:

The package for purity

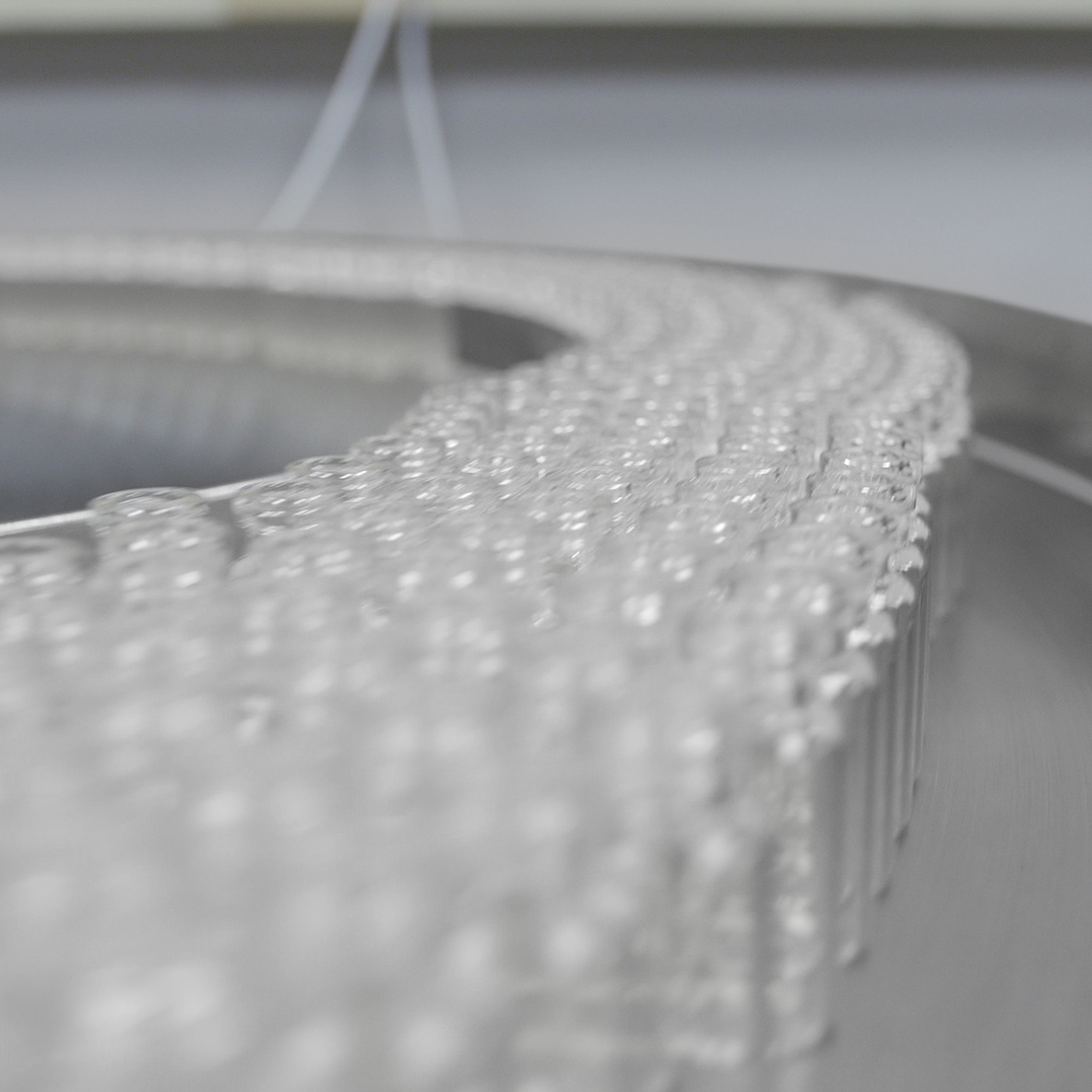

Valor pharmaceutical glass vials and containers are extremely damage resistant and significantly reduce particle generation. Valor glass containers have demonstrated up to a 96% reduction in peak particle counts on commercial filling lines, substantially reducing risk of particulate contamination.

Valor pharmaceutical glass vials and containers are extremely damage resistant and significantly reduce particle generation. Valor glass containers have demonstrated up to a 96% reduction in peak particle counts on commercial filling lines, substantially reducing risk of particulate contamination.

Prevents* Cracks

Not evolutionary – revolutionary

Prevents* Cracks

Not evolutionary – revolutionary

Valor pharmaceutical glass packaging is engineered with higher internal energy than conventional packaging. Damage introduced on filling lines or during shipping can create sub-visible flaws and cracks in conventional pharmaceutical packaging that can compromise drug product sterility and result in serious contamination. Valor glass is uniquely designed to prevent cracks and improve the quality of pharmaceutical packaging. This brings a higher level of protection to parenteral drugs and reduces the likelihood of global drug product recalls, supply interruptions, and drug shortages.

*In laboratory testing, Valor glass vials provided at least 30x protection against cracks than conventional borosilicate glass vials.

Valor pharmaceutical glass packaging is engineered with higher internal energy than conventional packaging. Damage introduced on filling lines or during shipping can create sub-visible flaws and cracks in conventional pharmaceutical packaging that can compromise drug product sterility and result in serious contamination. Valor glass is uniquely designed to prevent cracks and improve the quality of pharmaceutical packaging. This brings a higher level of protection to parenteral drugs and reduces the likelihood of global drug product recalls, supply interruptions, and drug shortages.

*In laboratory testing, Valor glass vials provided at least 30x protection against cracks than conventional borosilicate glass vials.

Enables Smoother Line Operations

A glass packaging solution engineered for pharma

Enables Smoother Line Operations

A solution engineered for pharma

In addition to eliminating delamination and dramatically reducing the probability of cracks, breaks and the risk of contamination by glass particles, the Valor pharmaceutical packaging technology enables smoother filling operations. Valor glass containers reduce line interventions, enabling lines to run at much higher speeds with improved yields. This results in more reliable access to medicines and vaccines for patients around the world.

In addition to eliminating delamination and dramatically reducing the probability of cracks, breaks and the risk of contamination by glass particles, the Valor pharmaceutical packaging technology enables smoother filling operations. Valor glass containers reduce line interventions, enabling lines to run at much higher speeds with improved yields. This results in more reliable access to medicines and vaccines for patients around the world.