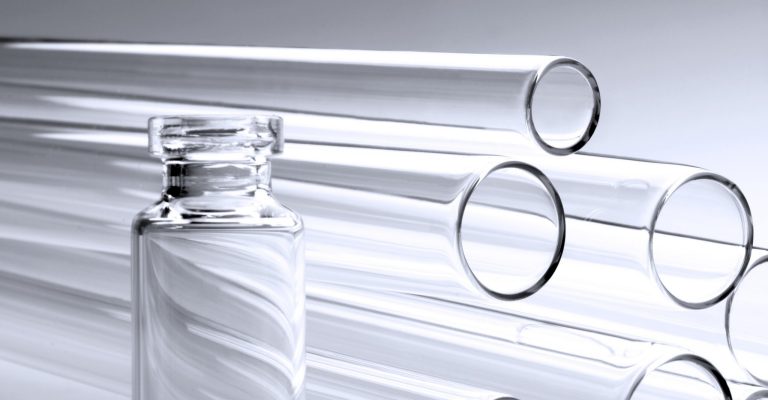

Tubular glass vials are derived from a pristine engineered glass tube raw material with a specific glass chemistry and typically combined with a rubber stopper and aluminum seal to complete the package. Choosing the right glass tubing for a vial application is vital in the pharmaceutical industry, where safety, purity, and stability are critical. Key considerations include chemical durability, surface quality, dimensional consistency, and regulatory compliance.

Corning, a globally recognized leader in glass and material science, proudly operates pharmaceutical tubing plants on three continents. With a legacy of innovation and quality, Corning offers glass tubing that meets the highest standards of performance and reliability, ensuring the integrity of pharmaceutical products. Our commitment to excellence and adherence to stringent industry regulations make Corning a trusted partner for pharmaceutical glass solutions.

Corning partners with our converting customers to provide a customizable tubing offering to help enable high converting yields. This customizable offering can include any combination of distinct lengths, levels of surface coating, or different end finishes. To maintain a pristine surface during transport and handling, the exterior surface of Corning's glass tubing is coated before final processing and packaging. Additional packaging options, including no glass-to-glass-contact during packaging and shipping, are also available.