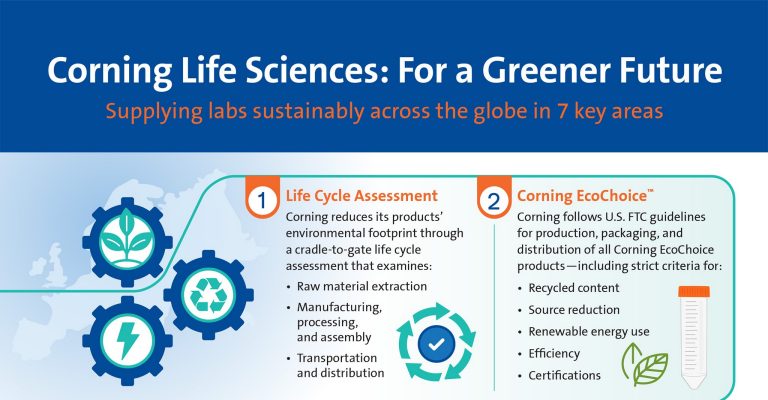

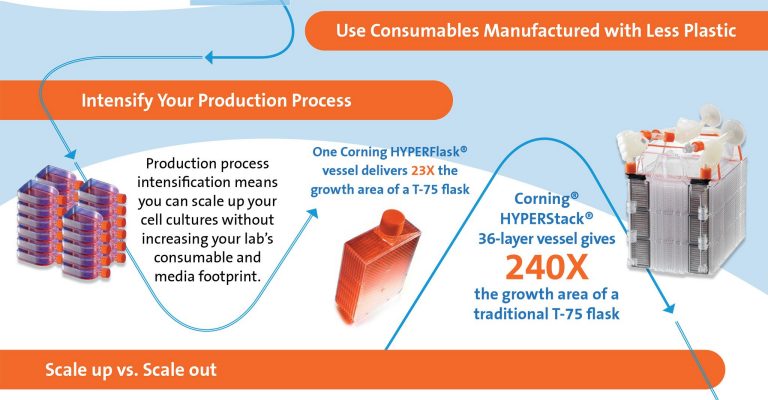

Corning is paving the way for cleaner air, cleaner water, and healthier generations to come. For Corning’s Life Sciences business segments this means bringing science to life sustainably, from research to drug delivery.

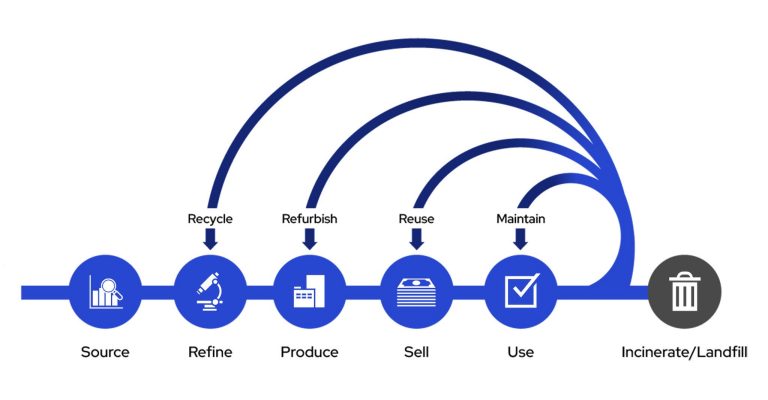

For us, sustainability means leveraging our heritage of innovation in new ways as we challenge ourselves to make our products, operations, and supply chains even more environmentally friendly. It means amplifying Corning’s social impact goals through a diverse and inclusive workforce and a commitment to community engagement.