Scalable Vaccine Production and Development

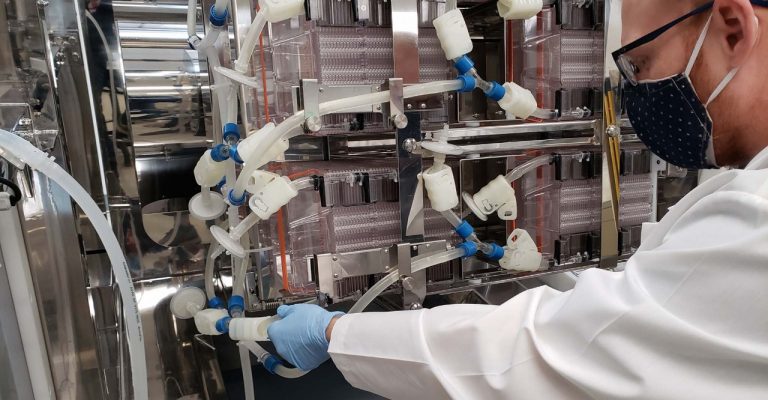

Corning provides a diverse set of single-use products for all your upstream vaccine development and manufacturing needs: from tried and true roller bottles for preliminary scale-up to space-saving and modular Corning® CellSTACK®, HYPERStack® and CellCube® vessels for ramping up vaccine production for clinical trials. And when your company is ready to transition to commercial manufacturing, the new Corning Ascent™ Fixed Bed Reactor System is an efficient way to produce large quantities of cells in a system that is designed to combine the benefits of adherent bioproduction platforms with the scale and automation of suspension manufacturing systems.

From initial vaccine process development through GMP manufacturing, our team of field application specialists is here to work alongside you every step of the way—from selecting an initial platform and defining your process in the lab to scaling up to full production. Look to Corning support your vaccine development and production and to help accelerate your journey to discovery.