A major challenge for manufacturing adherent cells for advanced therapies is producing the large quantities of cells needed in a cost-effective manner. To address the need for a more efficient solution, Corning developed the novel Ascent FBR System, a fixed bed bioreactor system designed to combine the benefits of adherent bioproduction platforms with the scale and automation of suspension manufacturing systems.

Overview

Improve Scale-up of Adherent Cells for Bioproduction

Improve Scale-up of Adherent Cells for Bioproduction

About

Learn more about the Ascent FBR System

The Ascent FBR:

The Ascent FBR:

- Features an innovative bioreactor designed to enable uniform media flow and uniform high-density cell growth

- Demonstrated to achieve greater than 90% transfection efficiency and high AAV-GFP vector yield/m2, which can reduce required runs and result in substantial cost savings

- Enables viable cell harvests for seed train and total viral particle capture and a path for other applications

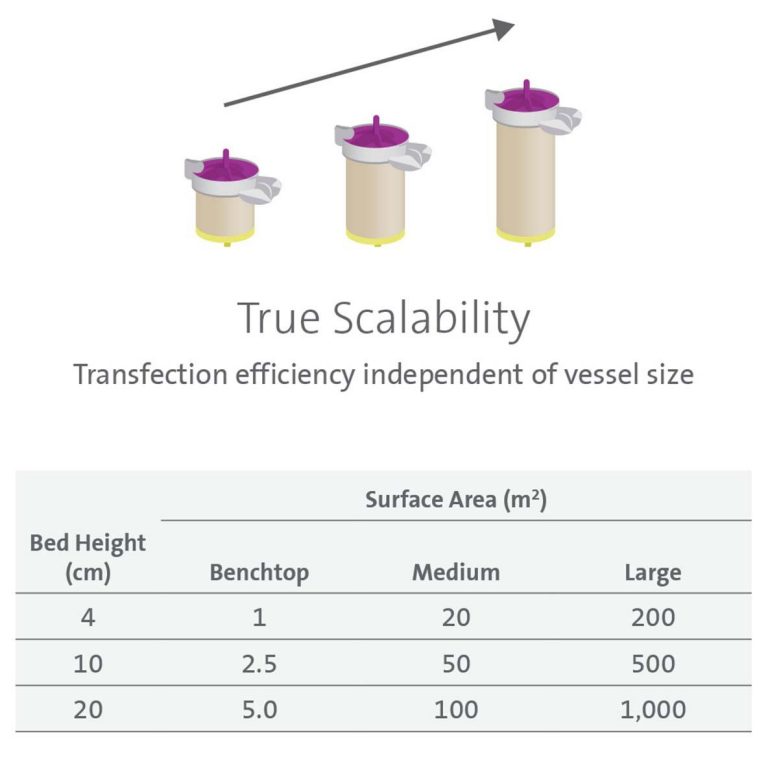

- Multiple Ascent FBR formats, from a 1 m2 benchtop system to 1,000 m2 production system, are planned to help create a stable and well-defined manufacturing process

- Allows for the use of chemical (detergent) or mechanical (freeze/thaw, microfluidization) cell lysis methods for the release of cell-associated viral vectors

- Features an innovative bioreactor designed to enable uniform media flow and uniform high-density cell growth

- Demonstrated to achieve greater than 90% transfection efficiency and high AAV-GFP vector yield/m2, which can reduce required runs and result in substantial cost savings

- Enables viable cell harvests for seed train and total viral particle capture and a path for other applications

- Multiple Ascent FBR formats, from a 1 m2 benchtop system to 1,000 m2 production system, are planned to help create a stable and well-defined manufacturing process

- Allows for the use of chemical (detergent) or mechanical (freeze/thaw, microfluidization) cell lysis methods for the release of cell-associated viral vectors

- The Ascent FBR System includes a system controller and single-use components including a bioreactor, media conditioning vessel, and other consumables, such as tubing, connectors, sensors, and bottles.

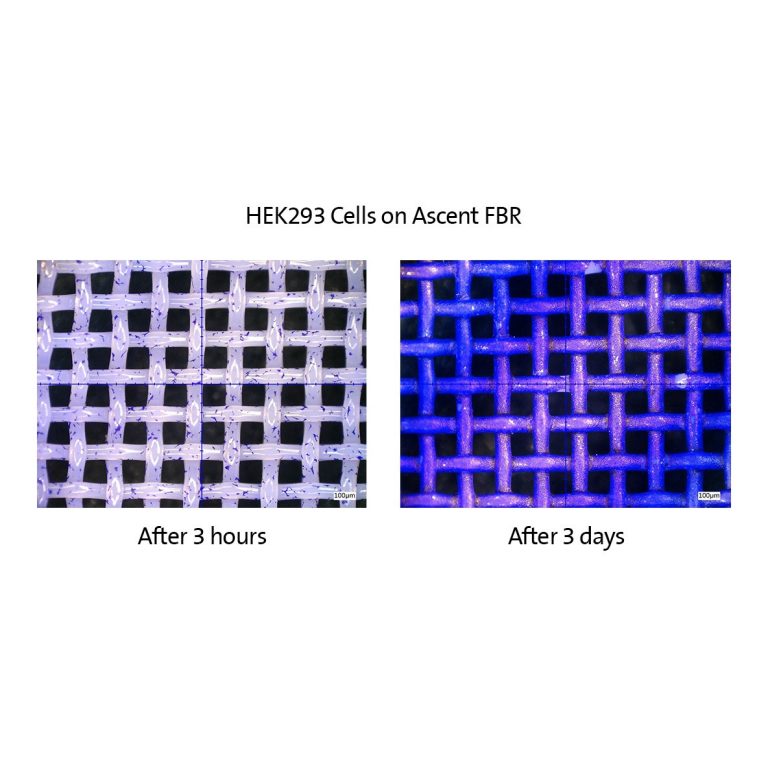

- The bioreactor's specially treated and packed polymer mesh enables uniform, low-shear fluid flow through the bioreactor bed, which promotes evenly distributed cell growth and enhances exposure of cells to nutrients and reagents.

- A separate conditioning vessel and recirculation loop enables flexibility in managing media conditions and developing optimal processes within the platform.

- The controller is designed to provide flexibility in protocol development and hands-off operation during use. Disposable sensors monitor key process parameters (pH, dissolved oxygen, temperature), and all fluid-contacting components are pre-assembled, single-use, and irradiated; no autoclaving required.

- The Ascent FBR System includes a system controller and single-use components including a bioreactor, media conditioning vessel, and other consumables, such as tubing, connectors, sensors, and bottles.

- The bioreactor's specially treated and packed polymer mesh enables uniform, low-shear fluid flow through the bioreactor bed, which promotes evenly distributed cell growth and enhances exposure of cells to nutrients and reagents.

- A separate conditioning vessel and recirculation loop enables flexibility in managing media conditions and developing optimal processes within the platform.

- The controller is designed to provide flexibility in protocol development and hands-off operation during use. Disposable sensors monitor key process parameters (pH, dissolved oxygen, temperature), and all fluid-contacting components are pre-assembled, single-use, and irradiated; no autoclaving required.

Request a Demo

Request a Demo

Request a DemoIf you’d like to see the Corning Ascent FBR System in action, please contact us to request an in-person demonstration.

If you’d like to see the Corning Ascent FBR System in action, please contact us to request an in-person demonstration.

Features and Benefits

Uniformity drives higher yield

: Uniformity drives higher yieldThe woven mesh of the bioreactor in the Corning Ascent FBR System is designed to enable uniform media flow, cell adhesion and cell growth resulting in significantly higher yield than competitive FBR systems. These images show even seeding of HEK293 cells after three hours (left) and subsequent even cell growth after 3 days (right).

Linear Scalability

: Linear ScalabilityThe Corning Ascent FBR System is designed to provide linear scalability from process development scale to production scale (1 square meter to 1,000 square meters) to create a stable, cost-efficient and well-defined manufacturing process.

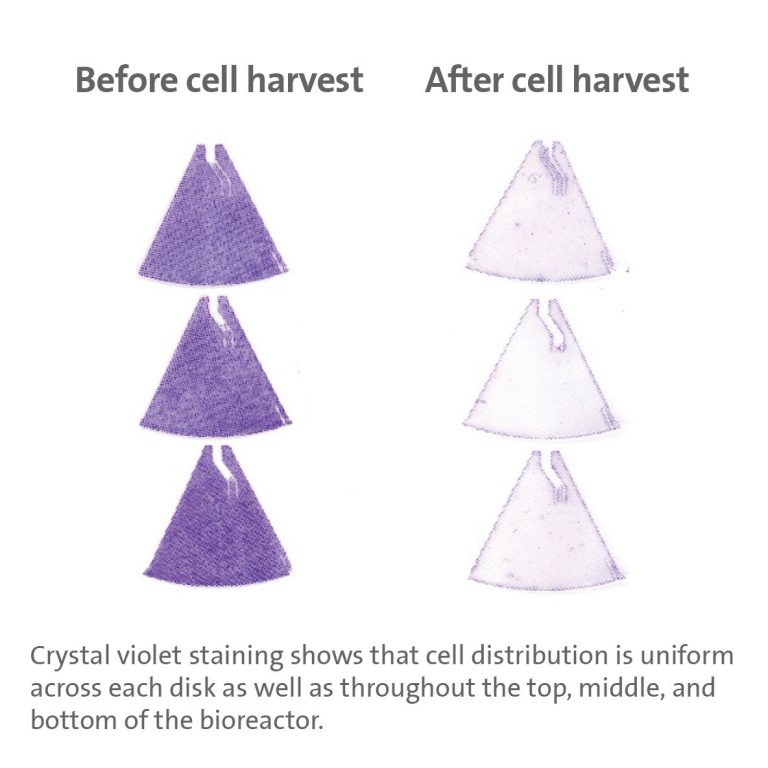

Cell Harvest

: Cell HarvestThe Ascent FBR is designed to harvest viable cells with >90% recovery and to be used for other applications that require the ability to harvest large quantities of cells, such as regenerative medicine and cell-based meat.

Order Corning Ascent Fixed Bed Reactor Products