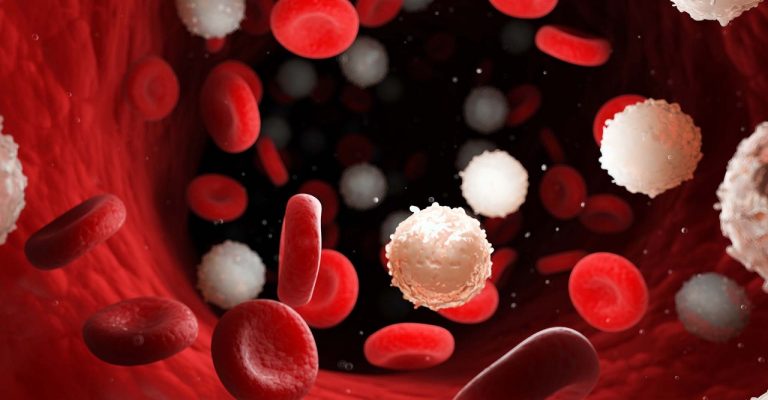

The US Food and Drug Administration’s approval of the first CAR (chimeric antigen receptor) T cell therapy was a key advancement in cancer therapy. As new T cell therapies continue to progress clinically, the need for autologous T cell manufacturing technologies that cost-effectively scale from pre-clinical to commercial production is becoming critical. Using the immune system to fight disease with CAR T applications has led to breakthrough advancements in disease management.

CAR T cell therapy is not without its challenges. These applications require complex manufacturing and supply chain protocols, CAR T models are high cost with strict requirements, and financial coverage for therapies in market is difficult to come by. As new T cell therapies continue to progress clinically, the need for autologous, streamlined T cell manufacturing technologies that cost-effectively scale from pre-clinical to commercial production is becoming critical.

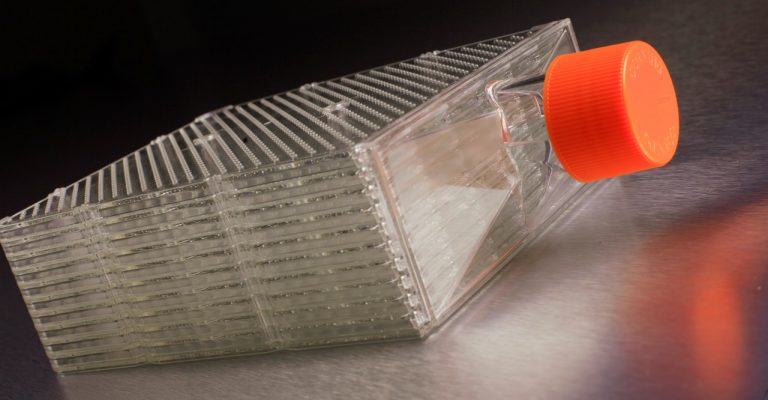

Corning understands your need for clinical cell expansion platforms that scale from research to commercial production. Leveraging our expertise in research-scale immune cell culture, we partner with cutting-edge US cancer centers to develop technologies designed to reduce manufacturing time and drive down production costs.

For example, the Corning® X-SERIES® Cell Separation Platform is the latest technology that can simplify your immune therapy cancer research by offering a series of systems that can automate many of the necessary steps involved in cell processing. This flexible, multi-system platform provides a streamlined solution with speed and performance gains in purifying mononuclear cells, washing contaminants from cell fractions, selecting specific cell populations, and concentrating cellular suspensions.

Whatever your immune cell research goals, let Corning’s portfolio of cell therapy solutions, along with support from our seasoned Field Application Specialists, partner with you along your path to discovery.