Once considered conceptual, gene therapy is now closer to reality. As gene therapy becomes more widely adopted, the need for larger batch sizes will ultimately conflict with the amount of available space in clean rooms. Already, there is an urgent need to produce more viral vectors per square centimeter. Corning is working to address the demand – with development efforts underway to increase yield.

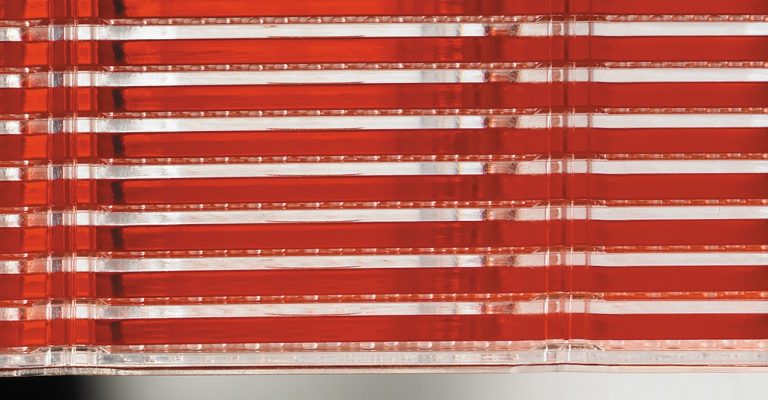

Building on a long and expert history in cell culture, Corning offers viral vector manufacturing platforms, such as Corning® HYPERStack® and CellSTACK® vessels. These are easily integrated into modular production set-ups enabling viral vectors to be produced at large scales. Customized closed-system connections allow multiple vessels to be manifolded together for efficient, single-batch processing. To continue to address the demands and challenges of manufacturing adherent cells for advanced therapies, Corning has developed the new Ascent™ Fixed Bed Reactor (FBR) System, which is designed to combine the benefits of adherent bioproduction platforms with the scale and automation of suspension manufacturing systems.